Jos already had experience with ULN2003 hardware (Darlingtons) and had some of these at home (in the cabinet labled U for ULN ;-) ). We used the circuit board to test this configuration, where we first used the +3.3Vpin of the Raspberry Pi, to set an input signal on the ULN2003.

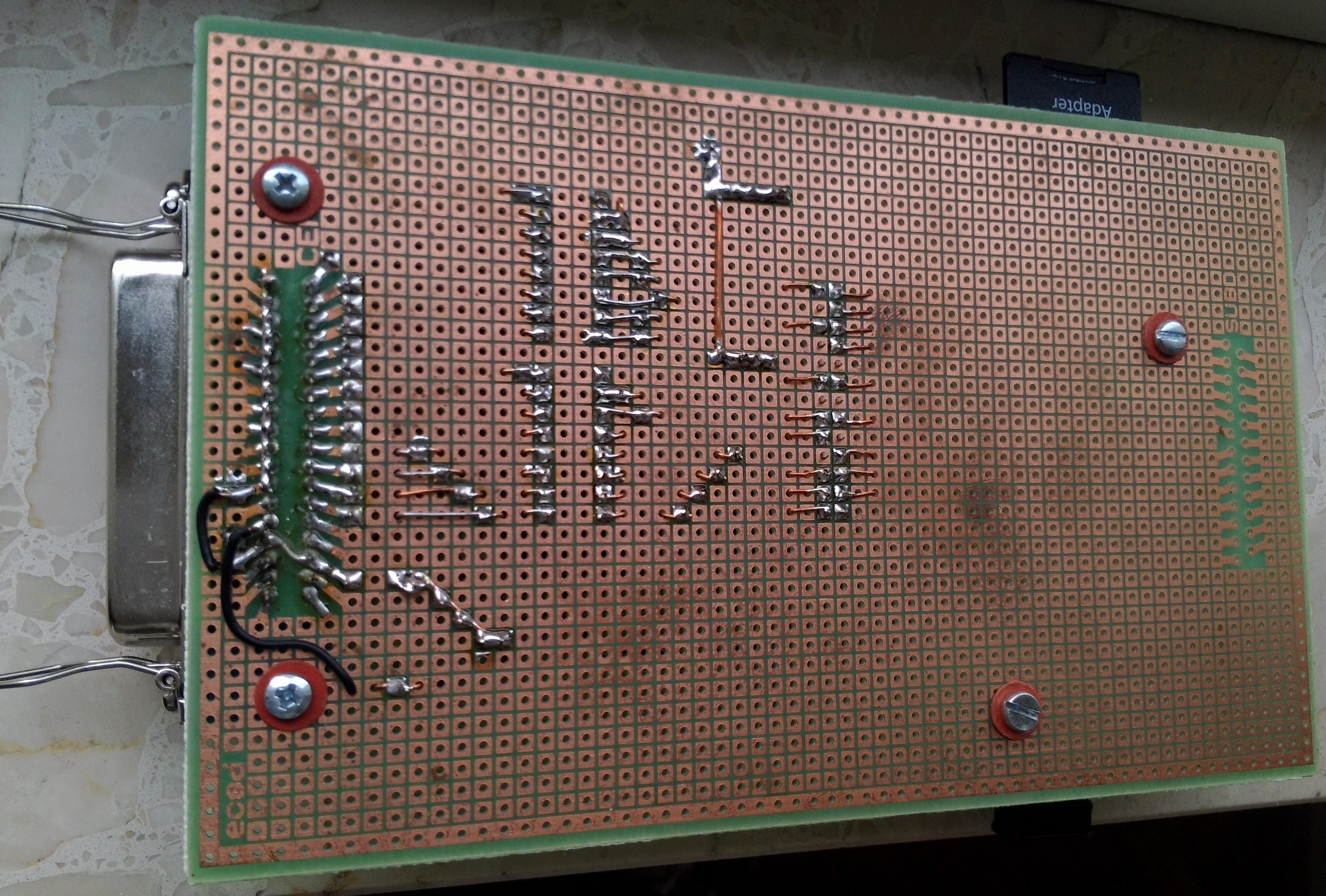

A poor man's sketch of the board looks like this:

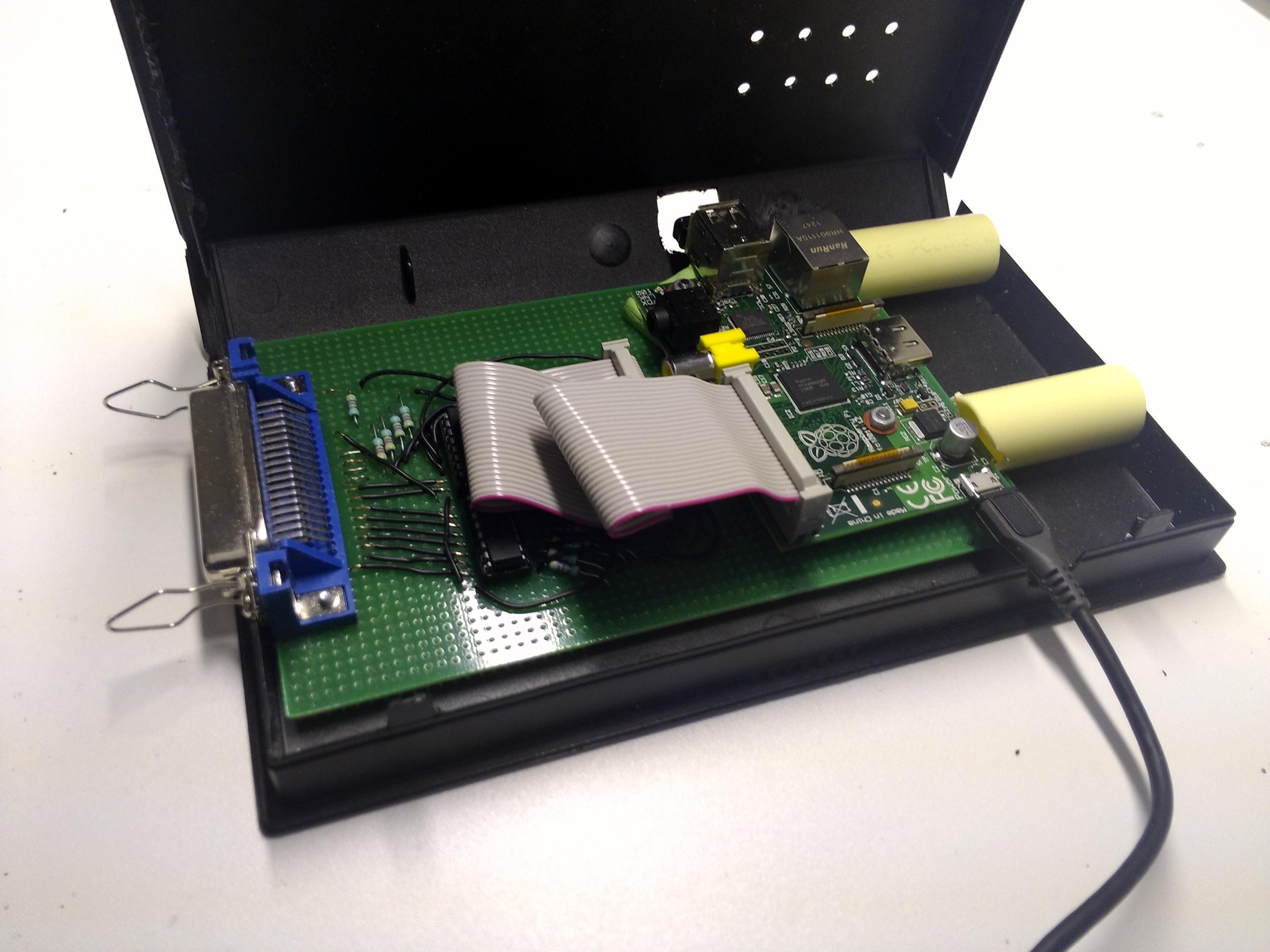

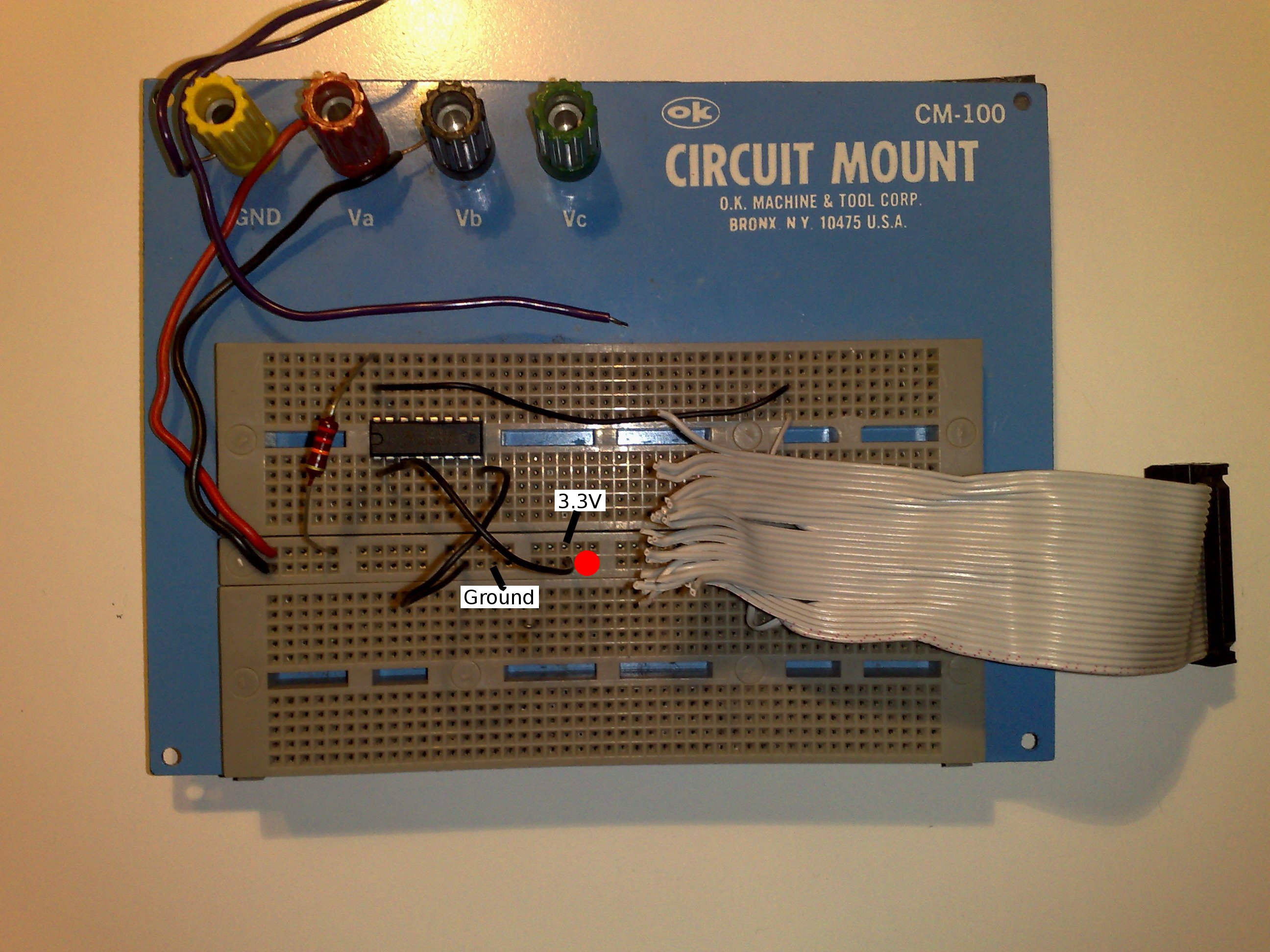

A picture, where you can see the flatcable, with pins 1, 6 and 16 connected to the board:

The photo shows the situation where the lower left pin of the ic is connected to ground. It can be switched to +3.3V by moving the black wire one hole up from it's current location (indicated by red dot in the image).

Be sure to set GPIO pin 23 to IN before you connect the Raspberry:

echo in >/sys/class/gpio/gpio23/direction

Once all is connected, you can see if the pin sees an input of 0 or 1 by giving the command:

cat /sys/class/gpio/gpio23/value

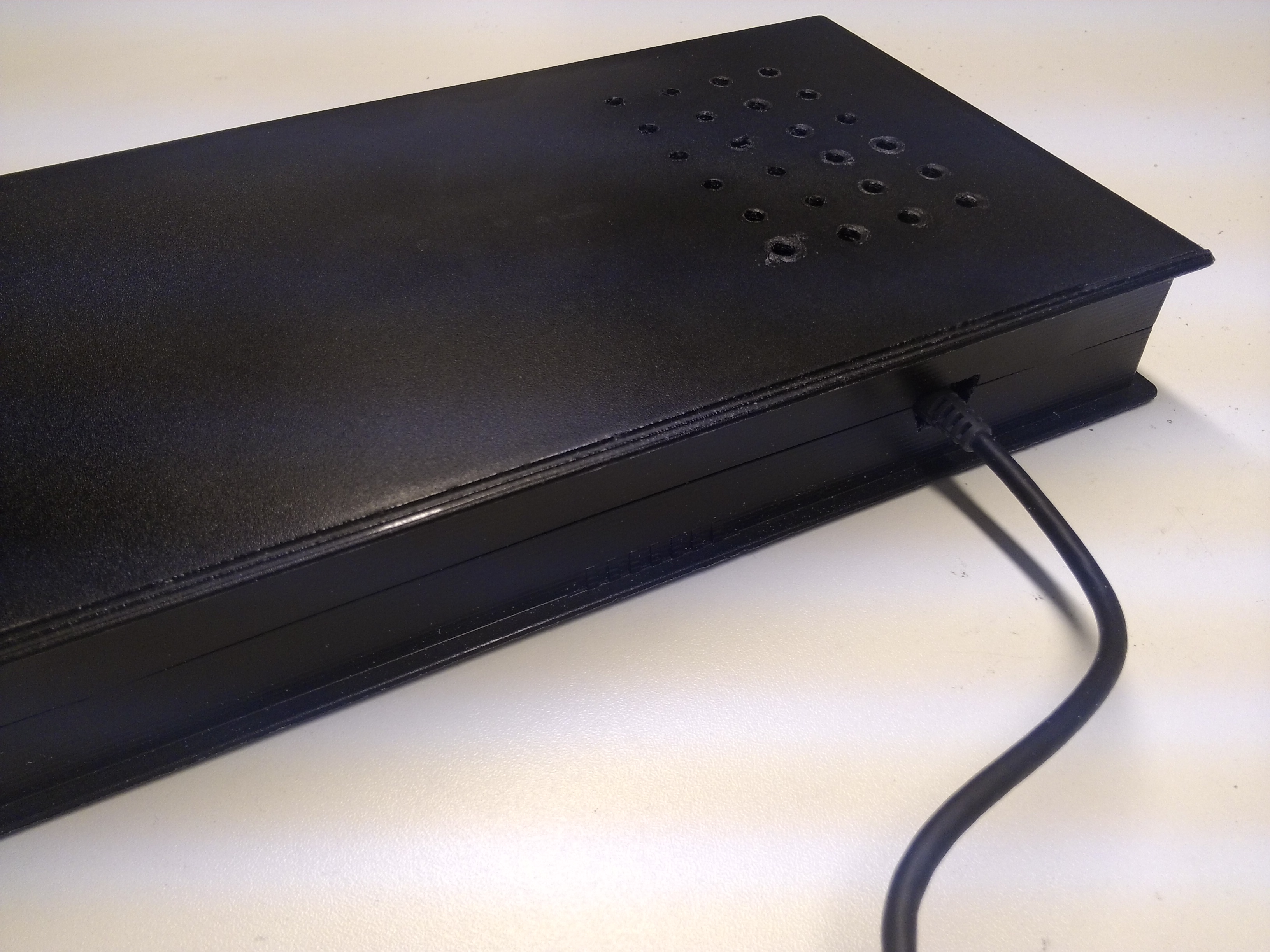

Secondly, we disconnected pin 6 from the board, and instead succesfully used an external power supply to supply 5V input level, as sketched below:

This concluded the experiments on the first night.